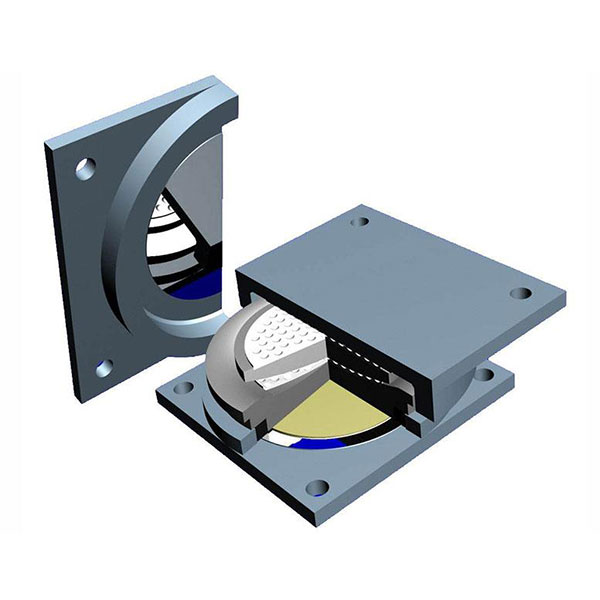

Modifies ultra-high molecular weight polyethylene (UHMWPE) have increased wear-resistance and load capacity, it is also suitable for use in sliding bearings for bridge and buildings. With grease dimples and high performance grease, a durable, low-friction sliding surface is ensure. Due to its high durability, the use of UHMWPE greatly reduced maintenance and replacement costs.

Modifies ultra-high molecular weight polyethylene (UHMWPE) have increased wear-resistance and load capacity, it is also suitable for use in sliding bearings for bridge and buildings. With grease dimples and high performance grease, a durable, low-friction sliding surface is ensure. Due to its high durability, the use of UHMWPE greatly reduced maintenance and replacement costs.

Installation of bridge supports

(1) The mounting plane of the support should be parallel to the sliding plane or rolling plane of the support, and the deviation of the parallelism should not exceed 2‰.

(2) Check the relative position of the top and bottom of the movable support before the support is installed.

(3) After the support is installed, the rolling and sliding planes should be horizontal, and the slope of the theoretical plane should be no more than 2‰. The center of the upper and lower plates of the support should be handled with a deviation of no more than 2‰.

(4) In order to ensure the installation of the support, it is generally necessary to build a 20~50mm thick dry and non-shrinking mortar cushion between the bottom of the support and the top surface of the professional name.

| Type | Shape | Size | Color |

| Arc support plate |

Round | Single piece φ1.5m or less | Black, white, gray and other colors can be customized |

| semicircular | Single piece semicircle length 1.5m or less | ||

| Plate support plate |

Long strip | Single piece length 4m, width1.5m | |

| whole plate | 1200*4000*5-7mm 1500*3000*5-7mm |